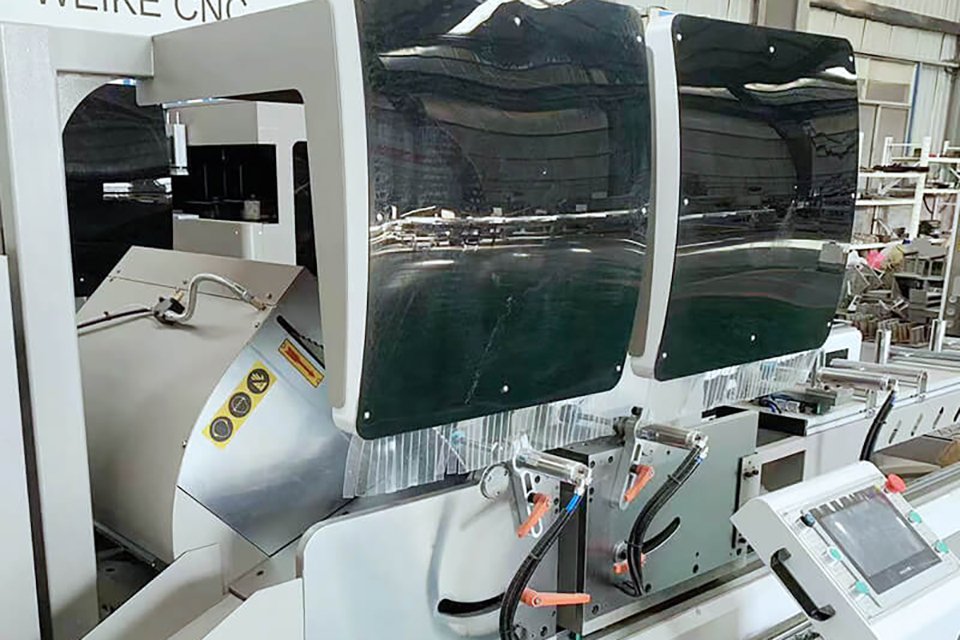

In today’s era of rapid technological advancements, CNC aluminum profile cutting saws are becoming increasingly popular. This trend has prompted numerous production and manufacturing companies to invest significantly in this advanced cutting technology, aiming to enhance production efficiency and output quality.

CNC aluminum profile cutting saws offer a wide array of advantages and functionalities, making them indispensable in modern industries. Firstly, through digital control, these saws achieve high precision and efficiency in cutting, thereby saving a considerable amount of time and labor costs. Secondly, by employing advanced cutting technologies, these machines produce parts with precise dimensions and high surface quality, reducing wastage and improving material utilization rates. Furthermore, CNC aluminum profile cutting saws boast automated operation and quick setup capabilities, enabling operators to handle the equipment easily and adjust parameters rapidly. This significantly boosts production efficiency and flexibility.

For industries requiring substantial aluminum profile processing, investing in CNC aluminum profile cutting saws is undoubtedly a wise choice. With this advanced equipment, companies can increase production efficiency, reduce manufacturing costs, enhance product quality, and achieve higher competitiveness and market share.

In conclusion, CNC aluminum profile cutting saws, as core equipment in the modern industrial field, not only meet the increasing demands of production companies but also bring more business opportunities and profits to enterprises. Investing in this cutting-edge technology will usher in new development opportunities and prospects for companies, positioning them at the forefront of innovation and efficiency in the competitive industrial landscape.